Choosing the right heater for a 3D printer bed isn't just about getting it hot. It’s a core engineering decision that makes or breaks print quality, reliability, and your machine’s reputation. For anyone sourcing components, the heated bed is ground zero for problems like part warping and failed first layers. Silicone rubber heaters have pulled ahead of older options like PCB heaters or bare wire coils for good reason. Let’s break down what the heated bed really needs and why silicone rubber is the go-to material for engineers who care about results.

The Real Problem: It’s All About Even Heat

A 3D printer bed has one job: keep the entire build surface at a rock-steady, uniform temperature. Spotty heating creates invisible lines of stress. One area expands slightly more than another, and suddenly your ABS print corners are lifting off the plate. It’s especially critical with high-performance materials that demand precise thermal management.

Data from manufacturing studies backs this up: temperature swings across the bed of just a few degrees Celsius can crank up internal stress in the printed part. The goal isn’t just to hit a target number on the dial; it’s to lock in that uniform heating across every square inch. We’re talking tolerances within a couple of degrees for serious printing.

Why Silicone Rubber Heaters Get It Right

The design of a silicone rubber heater reads like a checklist for solving the heated bed puzzle. Imagine a flat, resistive circuit—an “etched foil” element—sandwiched between layers of tough, flexible silicone. This isn’t just a heater; it’s a precision thermal engine.

The magic is in the etched pattern. Unlike a coiled wire that naturally creates hotter lanes, this pattern can be mapped out to spread energy perfectly evenly. For you, that means the heat signature across the bed is consistent. No mysterious cold zones, no unexpected hot spots. Just predictable, reliable performance that translates directly into higher print success rates and less wasted filament.

That silicone casing does more than hold things together. It’s a great conductor of heat, pushing energy efficiently into your aluminum or glass build plate. It’s also a durable insulator, protecting the circuit from moisture, physical knocks, and electrical issues. The heater’s thin, flexible profile is the final piece. It mounts flush against the plate, leaving no air gaps that would act as insulation. The result? You get to your target temperature faster and use less energy staying there.

What to Look For in a Supplier: Beyond the Spec Sheet

Picking a supplier for something this critical means looking under the hood. It’s the difference between a part that works and a component that elevates your entire machine.

Heating Uniformity is King. Ask for the data. A proper supplier should be able to provide thermal imaging reports showing the temperature map of their heater in action. The best ones use computational modeling to design their etch patterns, guaranteeing minimal variation—think ±2.5°C or better—edge to edge.

Durability Isn’t an Option. The build environment is tough. Look for heaters reinforced with fiberglass mesh, rated for continuous high-temperature operation. Insist on relevant safety certifications (UL, CE) for the construction. This isn’t just about longevity; it’s about preventing field failures that could idle a printer.

Precision Manufacturing Matters. A heater that’s off by a few millimeters throws off your entire assembly. Suppliers using CNC cutting ensure a perfect fit every time. Even more critical is end-of-line testing: every single unit should be tested for electrical resistance and dielectric strength (HIPOT tested). This is your guarantee that what arrives will perform exactly as specified.

Think System, Not Just Part. The heater is one piece of the thermal puzzle. A sophisticated supplier thinks about integration. They can co-locate precision temperature sensors exactly where your control board needs them. They’ll specify the right high-performance adhesive or thermal interface material to ensure a permanent, bubble-free bond that maximizes heat transfer. This systems-level support saves your engineering team time and headaches.

The Bottom Line for Your Bottom Line

For manufacturers building professional 3D printers, the heated bed is a critical differentiator. Opting for a silicone rubber heater is the smart technical choice. Choosing the right partner for that heater is the strategic business decision.

The right partner delivers more than a component; they deliver performance certainty. They provide the engineering data, the manufacturing rigor, and the integration support that de-risks your design. This translates into a machine that stands out for its reliability and print quality, giving you a real edge in a competitive market. In the end, that’s what sourcing is all about: finding partners who make your product better.

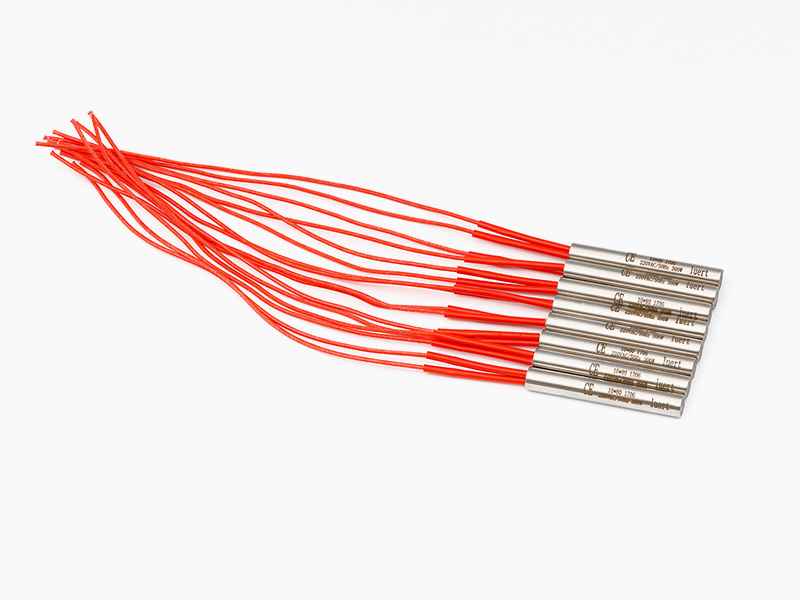

Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Silicone Rubber Heaters 12v silicone heating pad

Silicone Rubber Heaters 12v silicone heating pad Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters

русск

русск Español

Español