Engineering a custom silicone rubber heater moves beyond catalog shopping. It’s a precise exercise in thermal management where off-the-shelf solutions often fall short. For design engineers and procurement specialists in medical diagnostics, semiconductor packaging, or aerospace instrumentation, the success of your assembly hinges on a heater that performs as a perfectly integrated component, not an afterthought.

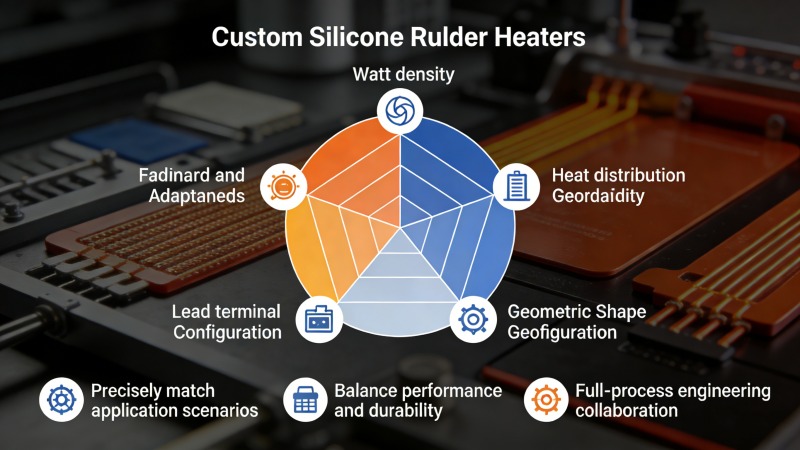

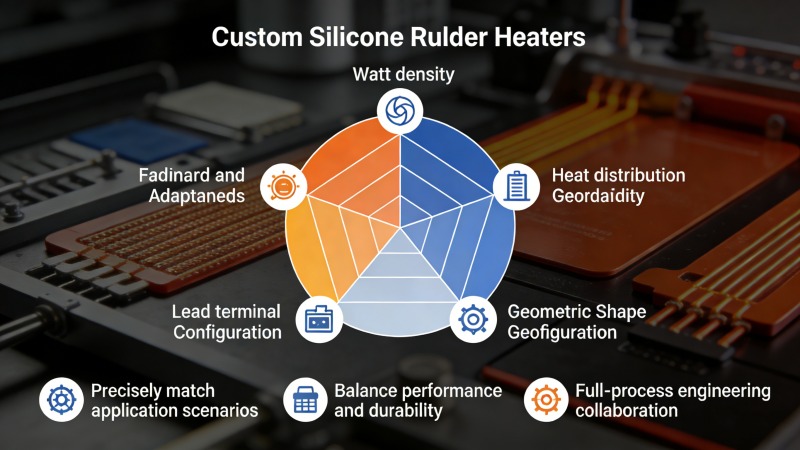

This guide details the five non-negotiable technical factors that define a high-performance custom heater. Mastering these parameters is the difference between a prototype that works on a bench and a product that thrives in the field.

1. Wattage Density: The Engine of Your Thermal Profile

Wattage density—expressed as watts per square inch (W/in²) or watts per square centimeter (W/cm²)—is the core power specification. It dictates how aggressively the heater can raise the temperature of your assembly.

Setting the wrong density is a fundamental error. Too high, and you risk thermal stress on the heater itself, degradation of adjacent materials, and dangerous hot spots. Too low, and the system cannot reach or maintain its target temperature, especially when factoring in thermal losses.

The Engineering Process: This isn’t guesswork. It’s calculated from your target temperature, the thermal mass of the substrate, heat loss to the environment, and desired heat-up time. For instance, a lightweight aluminum block in a controlled lab will have a vastly different requirement than a steel platen in an uninsulated industrial machine. The goal is to specify the minimum effective density to achieve performance reliably, maximizing efficiency and lifespan.

Supplier Differentiation: A competent supplier doesn’t just accept your wattage number. They question it. They run thermal simulations or leverage empirical data from similar applications to validate your calculation or suggest a safer, more efficient target. The right density balances performance with durability.

2. Thermal Profile & Uniformity: Heat Where You Need It

Uniform heating is a common requirement, but it’s not universal. Many applications demand a specific, non-uniform thermal profile—a gradient, a focused hot zone, or a pattern that excludes sensitive components.

The Design Lever: This is controlled through the custom etching of the resistive foil element. By varying the trace width and pattern density across the heater’s area, engineers can precisely map heat output. Think of it as a thermal inkjet printer, placing “heat pixels” exactly where required.

Application Example: A custom shape heater for a plastic welding fixture might need intense heat along a thin seal line and minimal warmth elsewhere. A diagnostic device may require a perfectly uniform plateau across a reagent well. The etch pattern is the tool that engineers this reality.

Why This Matters: Achieving true profile control requires sophisticated design software and manufacturing precision. Suppliers limited to simple, repeating trace patterns cannot deliver advanced thermal profiling, often resulting in compromised performance and iterative, costly prototype cycles.

3. Geometry & Form Factor: Conforming to Your Vision

The shape is often the primary driver for customization. Silicone rubber’ flexibility allows it to conform to flat, curved, or complex surfaces, but the design must account for mechanical realities.

Beyond the Outline: Specifying the silhouette is just the start. Key considerations include:

Bend Radii: How tightly must the heater flex? Exceeding the minimum bend radius of the etched foil element can fracture it.

Cut-Outs & Penetrations: Holes for mounting screws, sensors, or other hardware must be accounted for in the initial design, with proper lead-in and sealing to maintain integrity.

3D Forming: For heaters that must wrap a cylinder or compound curve, the design must account for material stretch and compression during forming to maintain trace integrity and wattage density.

The Manufacturing Link: A clean, dimensionally stable custom shape heater is a product of precision die-cutting or CNC machining. Fuzzy edges or dimensional drift are signs of poor process control, leading to fit and integration issues in your assembly.

4. Lead & Terminal Configuration: The Critical Interface

The electrical interface is a common point of failure. The placement, type, and strain relief of leads and terminals must be designed for the lifecycle of the product.

Strategic Placement: Leads should exit in a location that minimizes interference with other components, avoids pinch points, and simplifies assembly. For rotating or moving parts, flying leads or flexible extensions may be necessary.

Terminal Selection: Options range from simple insulated wire leads to ceramic terminal blocks, solder tabs, or quick-disconnect connectors. The choice is driven by current rating, environmental exposure (moisture, chemicals), and assembly process (soldering vs. screw clamping).

Strain Relief is Mandatory: A mechanical anchor point must be designed to absorb any push, pull, or twist on the lead, preventing stress from transferring to the delicate foil-to-wire junction inside the heater. This is often a reinforced “tail” or a clamped section.

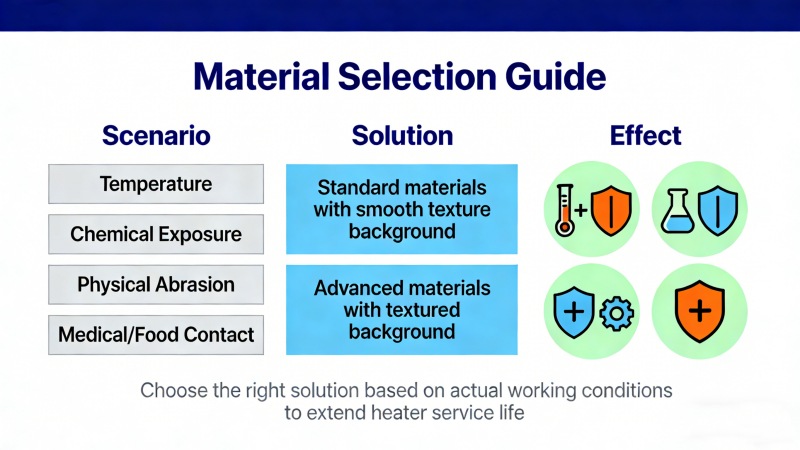

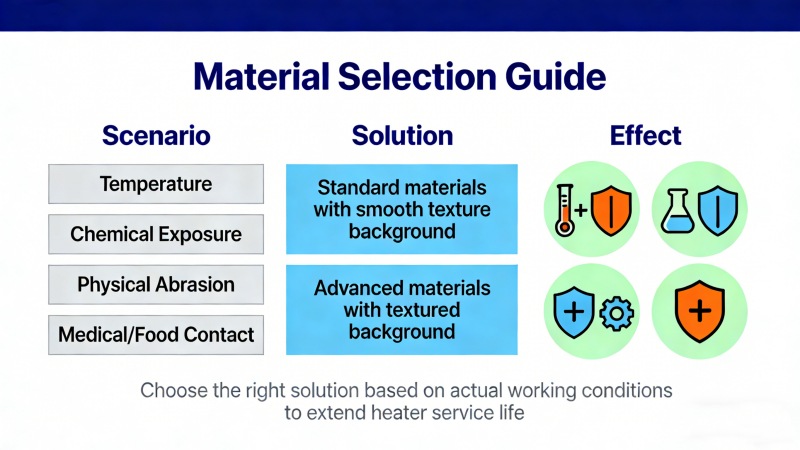

5. Materials & Environmental Integration

The operating environment dictates material selection. Standard silicone rubber is robust, but specialized conditions demand tailored solutions.

Key Material Decisions:

| Environmental Factor | Standard Solution | Advanced / Harsh Environment Solution | Purpose |

|---|

| Temperature | Standard Silicone (up to ~200°C) | High-Temp Silicone (up to 250°C+) | Maintains elasticity and insulation at continuous operating extremes. |

| Chemical Exposure | General-Purpose Formulation | Fluorosilicone or Specialized Compounds | Resists swelling, degradation from oils, fuels, or solvents. |

| Physical Abuse | Standard Build | Enhanced Fabric Reinforcement (e.g., thicker fiberglass) | Improves tear resistance and durability in high-vibration or handling applications. |

| Medical/Food Contact | Standard Industrial Grade | USP Class VI or FDA-Compliant Silicone | Meets biocompatibility or food-safe regulatory requirements. |

The Adhesive Layer: The bonding method—pressure-sensitive adhesive (PSA), thermal grease, or mechanical clamping—must be selected for thermal conductivity, permanence, and service temperature.

Partnering for Success: The Yuheng Engineering Protocol

Customizing a heater is a collaborative venture. At Yuheng, the process is structured to de-risk your project and ensure the delivered component is a perfect fit for your application.

Our Structured Engagement:

Discovery & Thermal Modeling: We begin by analyzing your target substrate, environment, and performance goals. Our engineers often employ thermal simulation to validate wattage density and profile designs before tooling begins.

Design-for-Manufacturability (DFM) Review: We provide a formal DFM report on your initial concept, flagging potential issues with bend radii, lead placement, or material limits. This step prevents costly mid-stream redesigns.

Prototype with Data: Prototypes are delivered with accompanying test reports (resistance verification, thermal imaging of profile).

Manufacturing with Traceability: Full production runs are executed under controlled conditions. Critical process parameters are monitored, and each heater can be traced back to its production batch and test data.

Our Technical Differentiators:

Precision Etched Foil Control: We design and etch our own elements, granting unparalleled control over thermal profiling to meet your exact uniformity or gradient specifications.

Integration-Ready Designs: We proactively design for the entire thermal system, offering co-located, calibrated sensors (thermistors, RTDs) and validated interface materials as a complete package.

Validation & Documentation: We provide the objective data—thermal maps, electrical test reports, material certifications—that your quality and engineering teams require for sign-off.

Conclusion: From Specification to Qualified Component

A custom silicone heater design is a critical, application-specific component. Its performance is predetermined by the rigor applied to these five factors: wattage density, thermal profile, geometry, lead configuration, and material science.

The supplier you choose becomes an extension of your thermal engineering team. The relationship must be built on technical dialogue, predictive engineering, and transparent validation. By focusing on these objective parameters and partnering with a supplier capable of navigating them with expertise, you transform a custom heater from a potential project risk into a certified, reliable driver of your product’s core functionality.

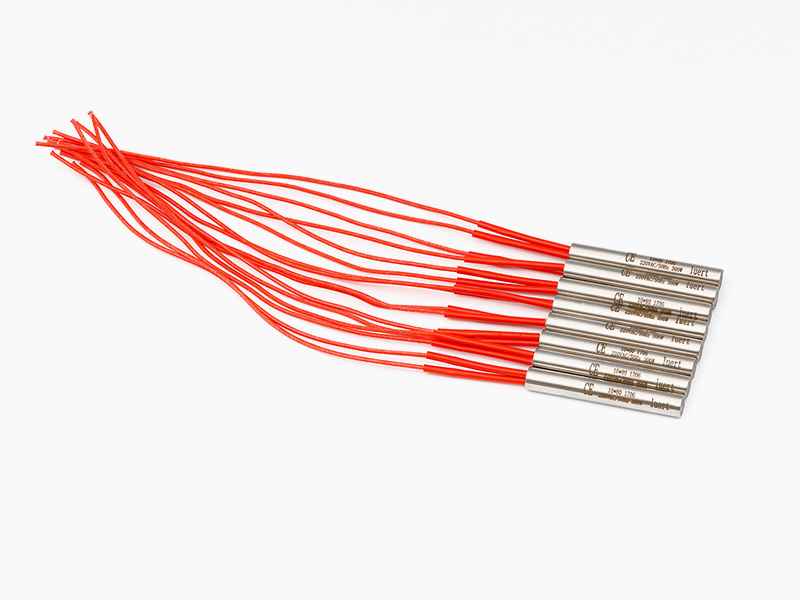

Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Silicone Rubber Heaters 12v silicone heating pad

Silicone Rubber Heaters 12v silicone heating pad Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters

русск

русск Español

Español