A silicone rubber heater fails. The machine it’s integrated into goes down. Production halts. For an engineer or plant manager, this isn’t just a component replacement; it’s an unplanned event costing thousands per hour in downtime, missed orders, and emergency maintenance.

The promise of a silicone heater is long-term, reliable operation—often for years. The reality for many ends in a premature failure measured in months. The disconnect usually stems from a misunderstanding of the component’s true limits. Failure is rarely random; it’s a predictable outcome of specific environmental stresses exceeding the design’s capabilities.

This analysis moves past marketing lifetimes to examine the fundamental physics and chemistry of failure. We identify the four primary, interlinked mechanisms that degrade silicone heaters and provide a framework for specifying and validating a heater that will survive your specific operational environment.

The Four Pillars of Premature Failure

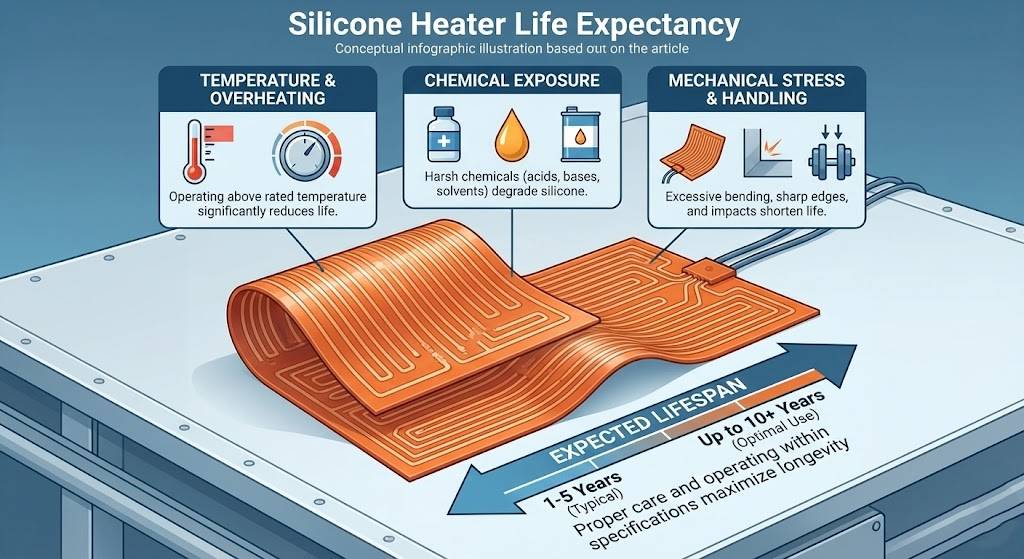

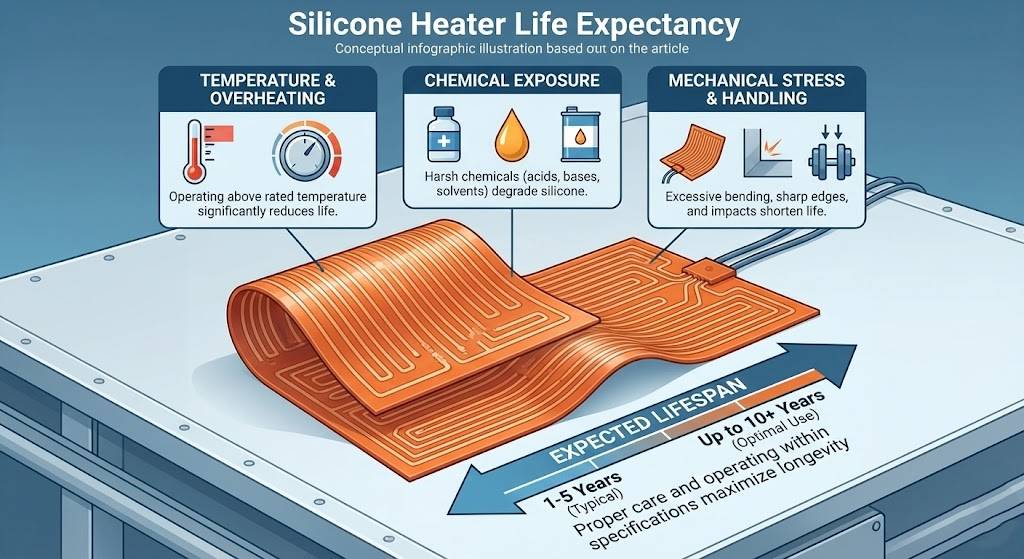

Silicone heater reliability is a battle against entropy waged on four fronts: thermal, electrical, chemical, and mechanical. An attack on one front often weakens the others, leading to a cascading failure.

1. Thermal Degradation: The Slow Burn

Every silicone elastomer has a functional temperature ceiling, typically between 200°C and 250°C for premium grades. Operating continuously near or above this limit initiates a process called polymer chain scission.

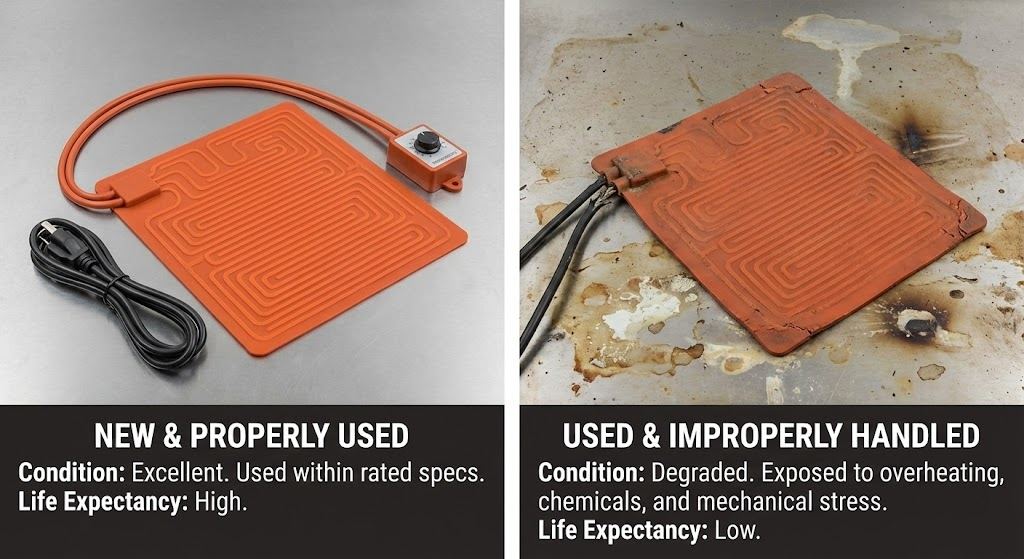

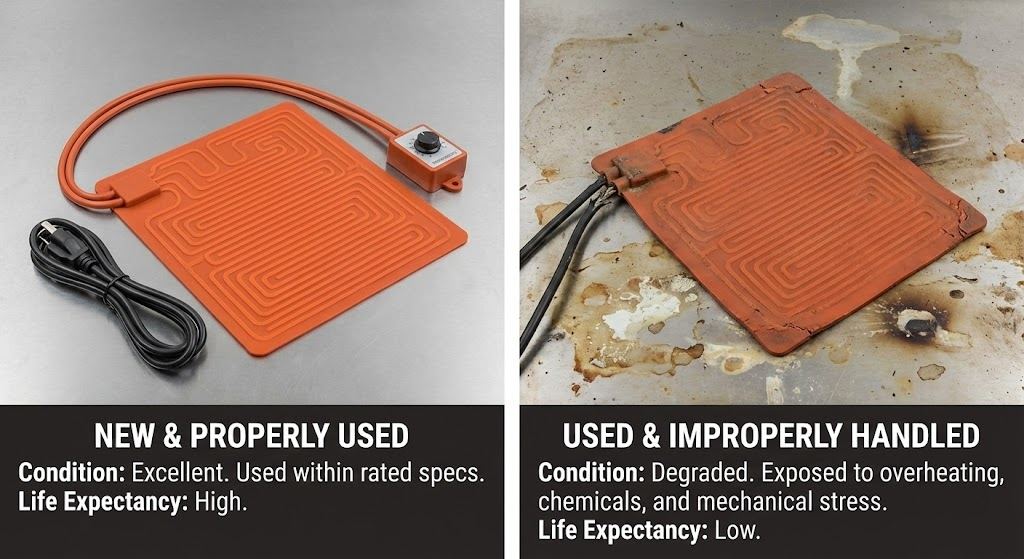

The Science: The molecular bonds in the silicone rubber begin to break down. This process is accelerated by the presence of oxygen. The material loses its elasticity, becoming brittle and crackly—a state known as embrittlement.

The Visible Evidence: You’ll see discoloration (yellowing to brown), a hardened surface, and micro-cracks. These cracks are not just cosmetic; they become ingress points for moisture and chemicals, accelerating failure. The heater might still conduct electricity, but its insulation properties are compromised, and it will tear easily during service or maintenance.

The Engineering Reality: The key metric is Continuous Operating Temperature, not a momentary peak. A heater specified for a 200°C surface temperature in an open-air oven is under far more thermal stress than one clamped tightly to a 200°C metal plate, where heat is efficiently wicked away.

2. Electrical Failure: More Than a Short Circuit

The etched foil element is robust, but its termination points—where the thicker lead wires are bonded—are inherent stress concentrators.

Cyclic Fatigue: The primary electrical killer is thermal cycling. The heater, leads, and substrate all expand and contract at different rates. With every on-off cycle, this differential movement flexes the delicate solder or weld joint at the termination. Over hundreds or thousands of cycles, metal fatigue sets in, leading to a high-resistance connection or a complete open circuit.

The Insulation Breakdown: This is where thermal and chemical degradation enable electrical failure. As the silicone insulation embrittles or swells from chemical attack, its dielectric strength drops. Under high voltage (even standard 120/240VAC), this can lead to a ground fault or a short circuit through the compromised insulation. A HIPOT (Dielectric Withstand) test is the standard quality gate to catch this pre-failure state.

3. Chemical & Environmental Attack: The Silent Saboteur

This is the most frequently underestimated factor. “Silicone” is not a single material; it’s a family of polymers with varying resistance.

Fluid Incompatibility: Certain fluids are aggressively hostile. Sharp hydrocarbon solvents, strong acids/bases, and high-pressure steam can cause swelling, extraction of plasticizers, or direct dissolution of the silicone matrix. A swollen heater loses mechanical strength and thermal conductivity; its performance becomes erratic.

The Critical Distinction: Immersion vs. Splash/Splash. A heater specified for a food processing line that endures daily caustic washdowns faces a completely different challenge than one in an automotive assembly area with occasional oil mist. The former requires a specialized, validated sealing strategy at the leads and edges; the latter may only need a standard formulation.

The Real-World Culprit: Plasticizer Migration. A heater mounted against certain types of vinyl, rubber, or PVC can experience a slow migration of plasticizers from the substrate into the silicone, softening it and causing it to lose shape and bond strength.

4. Mechanical & Installation Abuse

The heater is a component, not a structural member. Poor handling and installation inflict immediate damage or create a weakness that ensures future failure.

The Sharp Bend: Exceeding the minimum bend radius (often 5-10x the heater thickness) can fracture the etched foil element. The heater may work initially, but the microfracture will widen with thermal cycling, eventually creating an open circuit.

The Poor Bond: Using an incorrect adhesive or failing to prepare the surface creates air gaps. These are thermal insulators, forcing the heater to run hotter locally to transfer the same wattage, leading to localized thermal degradation (Hot Spots).

Inadequate Strain Relief: Leaving electrical leads unsupported, where vibration or accidental tugs can transmit force directly to the internal termination, is a guarantee of eventual failure.

The Specification & Validation Framework

Preventing premature failure is a proactive engineering discipline, not luck. Use this framework in your next procurement review.

| Failure Mode | Critical Spec to Demand | Application Question to Ask | Validation / Test to Require |

|---|

| Thermal Degradation | Continuous Operating Temp of the specific silicone compound used. | What is the steady-state surface temperature of the heater in its installed location? (Not the setpoint). | Request a TGA (Thermogravimetric Analysis) data sheet for the silicone. Review in-situ thermal imaging from a similar application. |

| Cyclic Electrical Failure | Cycle Life Rating at a given ∆T (e.g., 10,000 cycles from 25°C to 150°C). | How many on/off or power modulation cycles will it see per day/week/year? | Require termination pull-test data (e.g., >15 lbs force). Specify flexible, high-strand-count lead wires and proper strain relief. |

| Chemical Attack | Fluid Resistance Chart for the specific silicone grade against your listed chemicals. | Will it be immersed, splashed, or exposed to vapors? What is the concentration and temperature of the fluid? | Perform a compatibility soak test on a sample. For washdown, specify fully molded lead exits and perimeter sealing. |

| Mechanical Abuse | Minimum Bend Radius and Tensile Strength of the laminate. | How will it be handled during assembly? What is the installation path? | Inspect for clean, CNC-cut edges. Ensure clear installation drawings are provided. Verify PSA adhesion strength data. |

The Yuheng Protocol: Designing for a Verified Service Life

Our engineering process is built on the principle that a heater’s life expectancy must be a verified output, not a marketing input.

1. The Failure Mode Interview: Our technical questionnaire probes the unspoken environmental realities—clean-in-place procedures, UV exposure in inspection stations, the specific brand of hydraulic fluid used. We identify the dominant potential failure mode for your application first.

2. Material Science as a Tool: We don’t have one “silicone.” We select from a matrix of engineered elastomers. For a high-pressure steam environment, we might specify a platinum-cured, reinforced grade. For an oily automotive jig, a fluorosilicone compound might be the default.

3. Termination Engineering: We treat the lead connection as the primary failure point it is. Options range from laminated stress-relief pads to fully molded, hermetically sealed tubular exits, chosen based on vibration profiles and chemical exposure.

4. Delivering Forensic Evidence of Reliability: The final report with your prototype doesn’t just list specs. It includes the data that proves resilience: dielectric strength test results, termination pull-force validation, and chemical compatibility affirmations based on the specific compounds used.

Conclusion: From Hope to Predictability

A premature heater failure is a forensic event. The root cause—thermal overshoot, chemical incompatibility, cyclic fatigue—is written in the degraded materials.

The lifetime of a silicone heater is therefore not a mystery. It is the deterministic result of the interplay between its material construction and the sum total of environmental stresses it encounters. Lasting reliability is achieved by moving from a generic specification to a forensic analysis of the operational environment, and then partnering with a manufacturer whose engineering rigor is focused on defeating those specific failure mechanisms.

The goal is to make the service life of your thermal component a predictable, planned variable in your maintenance schedule, eliminating it as a source of operational risk. This level of certainty is the true return on investment of a deeply engineered custom solution.

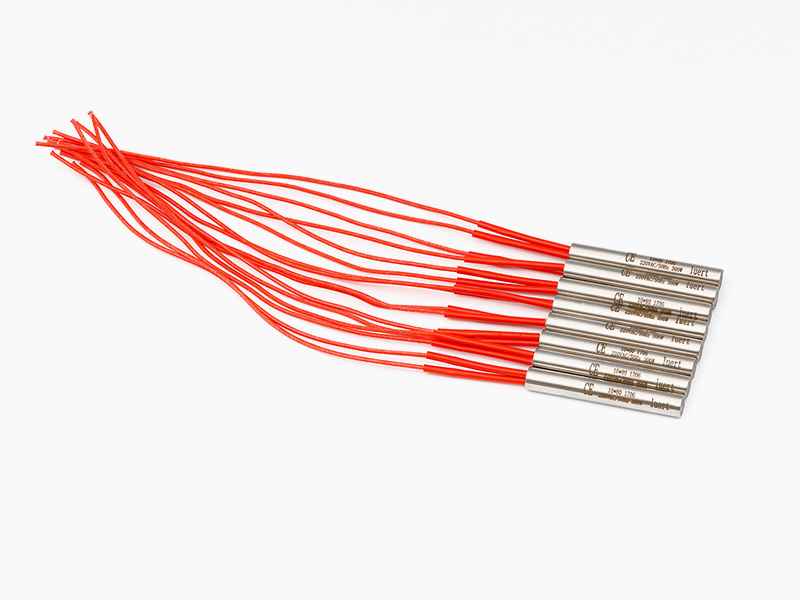

Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Silicone Rubber Heaters 12v silicone heating pad

Silicone Rubber Heaters 12v silicone heating pad Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters

русск

русск Español

Español