A critical failure in an outdoor telecommunications cabinet or a remote industrial control panel often starts invisibly. It’s not a lightning strike or a power surge. It’s the silent, persistent formation of condensation on the cold surfaces of sensitive circuitry, leading to corrosion, short circuits, and catastrophic system downtime. For network engineers and systems integrators, protecting these assets from the environment is a fundamental design challenge where thermal management is not about comfort, but about reliability and total cost of ownership.

This guide examines the physics of condensation in sealed enclosures, the limitations of traditional heating methods, and explains why modern, flexible silicone rubber heaters have become the engineered solution for reliable outdoor electronics protection. The focus is on specification, integration, and the measurable return on investment that comes from preventing moisture-related failures before they occur.

The Physics of Failure: How Condensation Destroys Electronics

Condensation occurs when the temperature of a surface inside an enclosure falls below the local dew point—the temperature at which the air can no longer hold its moisture. In outdoor applications, rapid nighttime cooling or seasonal temperature swings are the primary drivers. Even a "sealed" NEMA 4X enclosure contains air with residual humidity. When the internal metal walls or a dense circuit board cool faster than the ambient air inside, moisture condenses directly onto those cold surfaces.

The resulting water film is highly conductive. It creates leakage currents across insulated surfaces, leading to:

Electrochemical Migration: Metal ions from traces and components dissolve and redeposit, creating conductive dendritic growths (tin whiskers) that bridge circuits.

Corrosion: Oxidation and galvanic corrosion at connectors, terminals, and component leads increase contact resistance and lead to open circuits.

Mold & Fungus: In moderate climates, organic growth can further degrade insulation and block airflow.

The damage is cumulative and often irreversible. A study by the Institute of Electrical and Electronics Engineers (IEEE) on telecom failures identified moisture ingress and condensation as a leading contributory factor in over 30% of field failures for outdoor plant equipment. The solution is not just better sealing—it's precise thermal control to keep all internal surfaces consistently above the dew point.

The Limitations of Traditional Heating Methods

Engineers have long recognized the need for enclosure heating. Traditional solutions, however, introduce their own set of compromises.

Tubular Metal Sheathed Heaters: These "fire rod" style heaters are powerful but create intense localized heat. They often require significant clearance, can create thermal shadows (cold spots away from the heater), and consume more energy than necessary by heating a large volume of air convectively. Their rigidity makes them impossible to fit into compact or irregular spaces.

Forced Air Heaters with Fans: These systems actively circulate warm air, improving uniformity. However, they introduce moving parts (fans) that are a primary point of mechanical failure, require filters that need maintenance, and can draw dust and moisture into the enclosure if not perfectly sealed.

Simple On/Off Thermostats: Paired with any heater, a basic thermostat cycles the heater at full power. This creates temperature swings—the very condition that promotes condensation—and leads to higher energy consumption and thermal stress on the heater itself.

The ideal solution provides gentle, uniform warmth exactly where it's needed—on the walls and the components themselves—without moving parts, with minimal energy use, and in a form factor that fits modern, densely packed enclosures.

The Engineered Solution: Silicone Rubber Heaters for Precision Dew Point Management

Modern anti-condensation heaters built with silicone rubber technology are designed to address the specific failure modes of condensation. Their operation is based on conductive and radiant heat transfer, not convection.

How They Work: A thin, etched-foil element laminated inside layers of silicone rubber is adhered directly to the interior surface of the enclosure wall (typically the bottom or side). When powered, it turns the entire wall into a warm, radiant surface. This achieves two critical goals:

It keeps the wall temperature above the dew point, preventing condensation from forming on the largest surface in the enclosure.

By warming the wall, it creates a gentle natural convection current that circulates dry air and stabilizes the temperature of internal components, preventing cold spots on PCBs.

Key Advantages for Telecommunications & Outdoor Electronics:

| Design Feature | Engineering Benefit | Impact on Application |

|---|

| Low Watt Density & Uniform Heat | Gentle, even warmth (typically 1-5 W/in²) prevents localized overheating and minimizes thermal cycling of sensitive components. | Precise dew point control without creating thermal stress on adjacent electronics. |

| Conformability & Custom Shapes | Can be manufactured as a custom shape heater to fit around mounting studs, connectors, or irregular profiles, eliminating cold corners. | Maximizes usable space inside a crowded telecommunication cabinet; heat is applied precisely to problem areas. |

| Direct Surface Adhesion | Mounts flat with PSA, ensuring 100% thermal contact. Heat is conducted directly into the wall, not wasted heating air. | Higher efficiency (lower steady-state wattage) and faster response to temperature drops. |

| No Moving Parts & Solid-State Reliability | Entirely solid-state construction. Immune to vibration, dust, and fan failure. | Zero maintenance, ideal for remote, unattended sites. Lifetime measured in decades, not years. |

| Integrated Proportional Control | Can be paired with PID controllers or proportional DC power supplies for smooth, within-1°C temperature holding. | Eliminates temperature cycling, reduces energy consumption by up to 60% compared to on/off thermostats. |

Specification Guide: Designing an Effective Anti-Condensation System

Designing an effective system requires more than just sticking a heater on the wall. It requires a systematic analysis.

1. Calculate the Thermal Requirement.

The required wattage is not determined by the size of the enclosure, but by the heat loss. This is a function of:

Enclosure Material & Surface Area: Metal loses heat faster than fiberglass.

Worst-Case ΔT: The difference between the desired internal setpoint (e.g., 5°C above max expected dew point) and the lowest ambient temperature.

Insulation: Does the enclosure have internal insulation? This drastically reduces power needs.

A basic formula: Power (W) = [U-value x Surface Area (m²) x ΔT (°C)]. A qualified heater supplier will perform this calculation.

2. Map the Heat Distribution.

Where should the heat be applied?

Priority 1: The Floor. Cold air sinks. Heating the floor prevents the coldest air layer from forming.

Priority 2: Side Walls. Especially walls facing prevailing winds or shaded sides.

Priority 3: Strategic Components. A small, secondary heater can be adhered directly to the chassis of a particularly sensitive or high-mass power supply.

3. Select the Control Strategy.

For Basic Protection: A adjustable thermostat with a 2-3°C hysteresis is the minimum.

For Optimal Efficiency & Protection: A proportional (PID) controller with an NTC sensor mounted on the wall provides flawless, drift-free temperature maintenance, using the least possible energy.

The Yuheng Integration Advantage: From Component to System

Providing a heater is one thing. Providing a guaranteed condensation prevention system is another. Our process ensures your telecommunication cabinet heater is not just a part, but a validated solution.

Step 1: Environmental Analysis. We review your geographic location (for dew point data), enclosure specs, internal heat load from electronics, and required safety certifications (UL, ATEX for hazardous areas).

Step 2: Thermal Simulation. We model the enclosure to predict cold spots and recommend optimal heater placement and shape to ensure uniform surface temperatures above the dew point.

Step 3: Delivering a Complete Kit. We supply a ready-to-install package: the custom-shaped silicone heater with high-performance PSA pre-applied, integrated temperature sensor (if required), and vetted compatibility with recommended controllers.

Step 4: Validation Data. We provide expected performance metrics: steady-state power consumption, heat-up times, and temperature uniformity maps, giving you engineering certainty before installation.

Conclusion: An Investment in Predictable Uptime

In critical network infrastructure and industrial IoT, unplanned downtime is measured in tens of thousands of dollars per hour. Condensation is a predictable environmental threat, and therefore, protecting against it must be a predictable, engineered function.

An anti-condensation heater system based on flexible silicone rubber technology represents a mature, optimized solution. It moves beyond the crude "add heat" approach to a precision strategy of dew point management. By specifying a system designed for uniform surface warming, low energy draw, and flawless reliability, engineers transform a potential point of failure into a cornerstone of system integrity. The result is not just a protected enclosure, but a significant reduction in life-cycle costs through eliminated maintenance, prevented failures, and optimized energy use—a decisive return on investment for any outdoor asset.

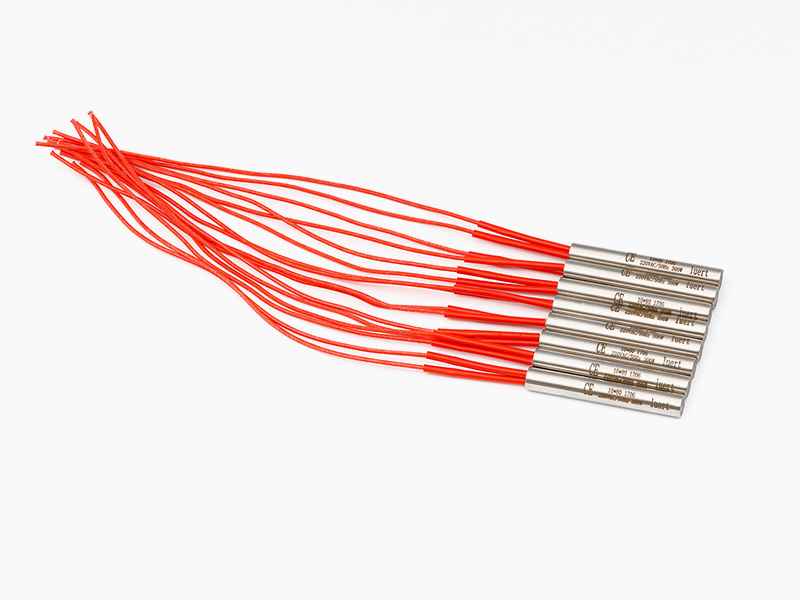

Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Silicone Rubber Heaters 12v silicone heating pad

Silicone Rubber Heaters 12v silicone heating pad Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters

русск

русск Español

Español