The rapid charge loss, sluggish power delivery, and frustrating “charging refused” alerts in cold weather are more than just inconveniences for electric vehicle owners or operators of grid-scale energy storage. They are symptoms of a fundamental electrochemical limitation: lithium-ion batteries suffer in the cold. For engineers designing battery packs for EVs, commercial vehicles, and stationary storage, overcoming this limitation is a non-negotiable requirement for market viability in northern climates. It’s not merely about driver comfort; it’s about unlocking rated capacity, ensuring reliable start-ups, enabling fast charging, and, most critically, preserving the long-term health and safety of the battery asset.

This technical analysis moves beyond the symptom to the root cause, examining the physics of low-temperature battery performance. It then details why modern, flexible heating systems are an essential, active component of advanced EV thermal management, explaining how they must be engineered not just for warmth, but for precision, uniformity, and absolute safety.

The Cold Hard Facts: How Low Temperatures Degrade Battery Function

A lithium-ion battery’s performance is governed by the kinetics of lithium-ion movement between anode and cathode. Cold temperatures severely impede this process, triggering a cascade of negative effects:

Increased Internal Resistance & Voltage Sag: The electrolyte becomes more viscous, and ion diffusion slows dramatically. This leads to a sharp rise in internal resistance. Under load, this causes significant voltage drop (“sag”), reducing available power and triggering premature low-voltage shutdowns, cutting usable range by 30-50% in sub-zero conditions.

Lithium Plating & Irreversible Damage: During charging in cold temperatures, lithium ions cannot intercalate quickly enough into the graphite anode. Instead, they plate as metallic lithium on the anode surface. This lithium plating is permanent. It consumes cyclable lithium (reducing capacity) and, critically, creates dendritic structures that can grow and pierce the separator, leading to internal short circuits and thermal runaway—a primary safety risk.

Severely Inhibited Charging: Charging protocols (especially fast charging) are heavily restricted or disabled below ~0-5°C by the Battery Management System (BMS) to prevent the plating described above. This renders rapid charging infrastructure useless in winter and makes overnight charging of fleet vehicles or storage systems inefficient.

A study published in the Journal of The Electrochemical Society quantified that charging at -20°C can cause plating severe enough to reduce cell capacity by over 10% in fewer than 50 cycles. Passive insulation alone only delays the inevitable; once a pack is cold-soaked, it stays cold. The only engineering solution is active, controlled heating.

The Heating Imperative: Why Uniformity is as Critical as Temperature

Heating the battery pack is a solved problem in concept. The challenge lies in execution. Applying heat unevenly or aggressively creates new, more dangerous problems than the cold itself.

The Danger of Localized Hot Spots: Traditional solutions like small ceramic heaters or resistance wires create intense heat in a confined area. This can lead to significant temperature gradients across the battery module. Cells near the heater overheat, accelerating degradation, while distant cells remain too cold. This imbalance stresses the pack, reduces overall life, and in a worst-case scenario, can initiate thermal runaway in a single cell that propagates to others.

The Engineering Goal: The objective is not to make the pack “hot.” It is to raise the entire mass of cells uniformly and gently to their optimal, narrow operating window (typically 15-25°C) as quickly and efficiently as possible, and to maintain that uniformity during operation.

Why Flexible Silicone Heating Pads Are the Engineered Solution

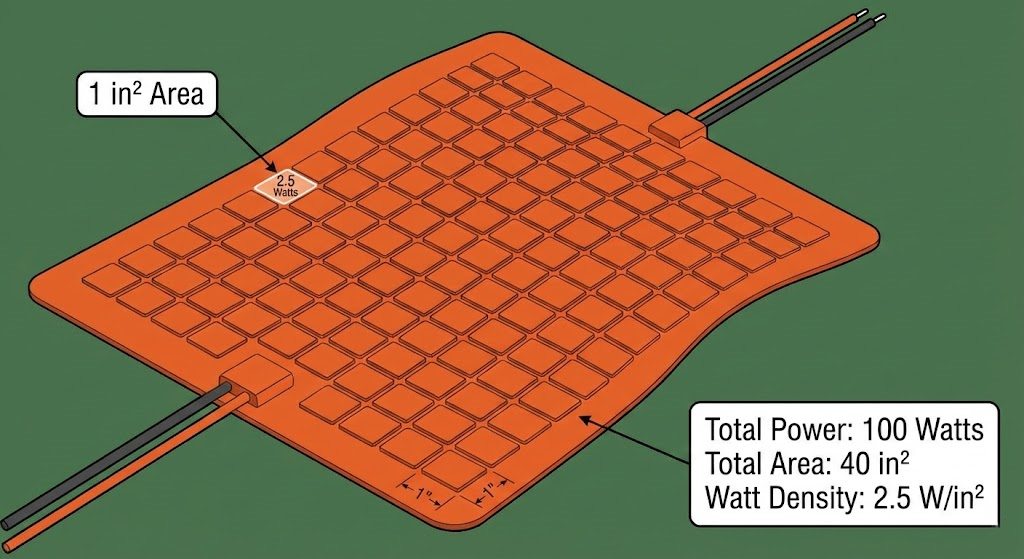

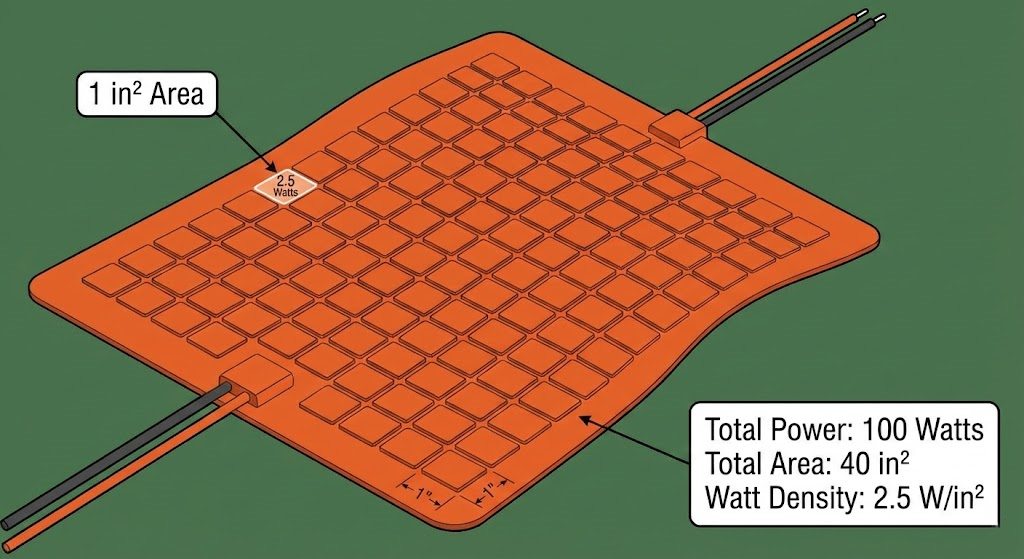

A modern flexible battery heater, constructed with an etched-foil element laminated in silicone rubber, is designed specifically to meet the stringent requirements of battery thermal management.

Key Advantages for Battery Pack Integration:

| Design Characteristic | Engineering Benefit for Battery Packs | Impact on Performance & Safety |

|---|

| Conformable & Thin Profile (<1mm) | Can be directly adhered to the flat surface of a cell or module, becoming part of the pack structure without adding significant volume or weight—critical for EV energy density. | Enables lightweight thermal solutions. Maximizes space for active battery material. |

| Exceptional Heating Uniformity | Etched-foil elements distribute heat evenly across the entire pad surface, eliminating dangerous hot spots and ensuring all adjacent cells see the same ΔT. | Prevents localized overheating and cell-to-cell stress. Enables safe, faster heating rates. |

| Rapid Thermal Response | Low thermal mass and direct conductive contact allow the heater to transfer >90% of its energy directly into the cell surface immediately. | Reduces time-to-temperature, improving vehicle readiness and energy efficiency. |

| Robust & Electrically Safe | Silicone rubber is an excellent dielectric (withstand voltages >4kV), resistant to mild compression, and can be specified with flame-retardant properties. | Provides long-term reliability and a critical insulation barrier in high-voltage environments. |

| Precision Zone Control | Multiple independent battery heating pads can be configured and controlled for different modules or areas of a large pack, matching thermal demand precisely. | Allows for optimized, efficient heating of only the sections that need it. |

System Integration: The Critical Role of Control and Sensing

The heater is merely the actuator. The intelligence comes from the control system, which must be designed with safety as its first principle.

1. The Sensor Network: Reliable heating requires accurate, redundant temperature sensing. Typically, at least one NTC or RTD thermistor is required per major heating zone, placed to monitor the temperature of the cell surface, not just the heater or ambient air.

2. The Control Logic (BMS Integration): The heater must be slaved to the Battery Management System. A safe protocol involves:

Pre-conditioning (Before Charge/Drive): The BMS triggers heating when plugged in or pre-start, bringing the pack to optimal temperature before accepting high current.

Dynamic Regulation (During Operation): In very cold climates, low-power heating may be maintained during discharge to prevent re-cooling.

Graceful Shutdown: Heaters must de-energize if a sensor fails, communication is lost, or any cell voltage/temperature goes outside a strict safe window.

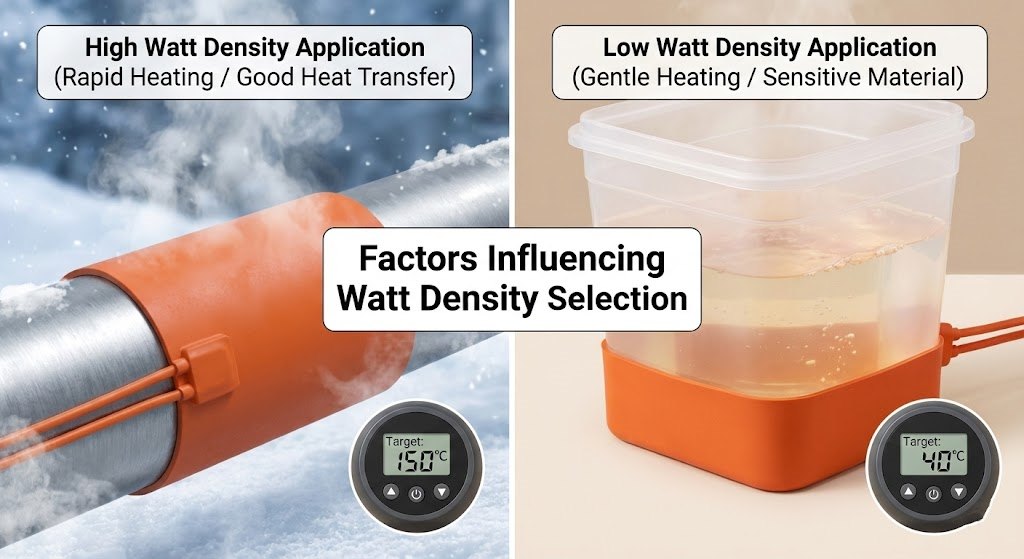

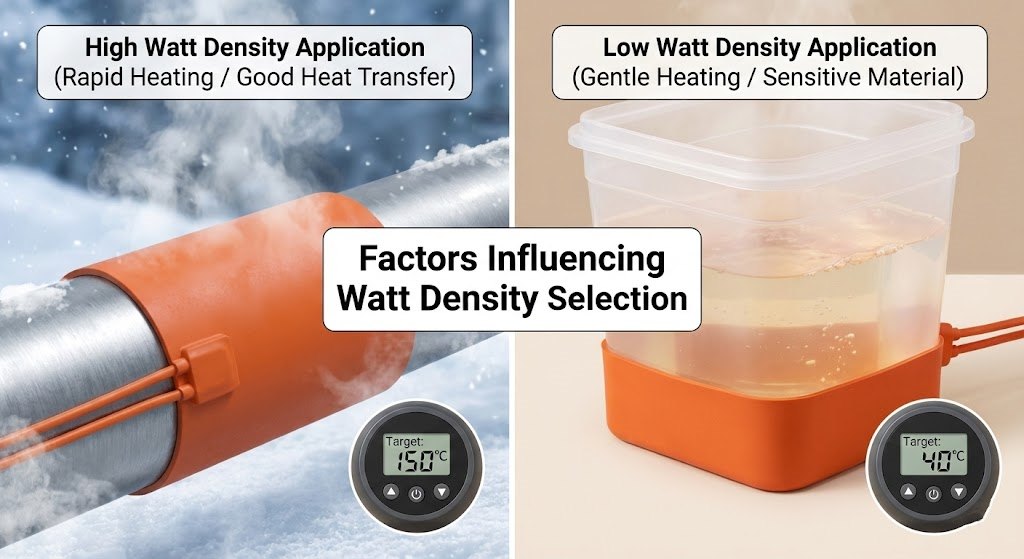

3. Power Design: Heaters are typically low-voltage (12V, 24V, or 48V) to align with vehicle auxiliary systems. Power density is carefully calculated to provide a safe heating rate (often 0.5-2°C per minute) to avoid thermal stress.

The Yuheng Design Protocol for Battery Safety

Designing a heating system for a lithium battery pack is a safety-critical activity. Our engineering process is structured to mitigate risk at every stage.

Phase 1: Cell & Pack Thermal Analysis.

We start by modeling the thermal characteristics of your specific cell chemistry and module geometry. This determines the total wattage required, the number of heating zones, and optimal pad placement (e.g., on end plates, between cells, or on the cooling plate) to achieve target warm-up times without exceeding safe surface temperatures.

Phase 2: Safety-First Component Specification.

Material Selection: We specify UL 94 V-0 rated, flame-retardant silicone compounds.

Dielectric Strength: We design for insulation significantly beyond system voltage requirements.

Termination & Sealing: Leads are equipped with high-temperature insulation and sealed exits to prevent moisture ingress, a critical factor for long-term reliability.

Phase 3: Control Interface Co-Design.

We provide clear, standardized electrical interfaces and communication protocols (e.g., PWM control, CAN bus-ready analog input) to ensure seamless integration with your BMS team, reducing development friction.

Phase 4: Validation & Documentation.

We supply not just heaters, but validation dossiers: thermal imaging reports demonstrating uniformity, dielectric withstand certificates, and lifetime cycle testing data under simulated environmental conditions.

Conclusion: From Liability to Managed Asset

In cold climates, a lithium battery without thermal management is a compromised asset—its performance diminished, its lifespan shortened, its safety margin reduced. An integrated, flexible heating system transforms this liability.

It is no longer an optional accessory but a core enabling technology for lithium battery cold weather performance. By enabling uniform, rapid, and precisely controlled warming, it ensures that batteries deliver their promised range, accept fast charging year-round, and do so while operating within the safest possible electrochemical window.

For pack engineers and OEMs, this translates directly into a product that is competitive in all markets, resilient in all seasons, and trustworthy in the hands of the end-user. Specifying a heated battery system is, therefore, a decisive investment in product integrity, customer satisfaction, and the fundamental safety of electrified transportation and energy storage.

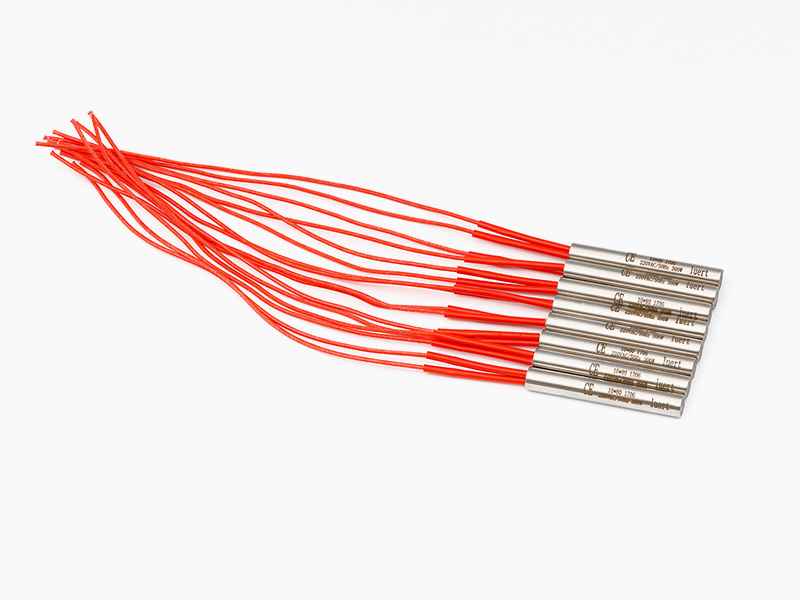

Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Cartridge Heaters Cartridge Heaters

Cartridge Heaters Cartridge Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Tubular Heaters Tubular Heaters

Tubular Heaters Tubular Heaters Silicone Rubber Heaters 12v silicone heating pad

Silicone Rubber Heaters 12v silicone heating pad Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters Silicone Rubber Heaters

Silicone Rubber Heaters Silicone Rubber Heaters

русск

русск Español

Español