Selecting a heater for your 55-gallon drum might seem straightforward, but the critical choice between metal and plastic drums dictates everything—from the type of heater you can use to the safe operating power. A common and costly mistake is applying a high-wattage heating solution designed for a steel drum onto a polyethylene one, risking damage, chemical leakage, or worse.

This guide cuts through the confusion. As specialists in industrial thermal solutions, we'll clarify the material science behind safe heating, provide clear selection criteria, and highlight why understanding the 55 gallon drum heater specifications for your specific drum type isn't just about efficiency—it's a fundamental safety requirement.

The Core Difference: Why Material Dictates Your Heating Strategy

Metal (typically steel) and plastic (typically HDPE or Polyethylene) drums react to heat in fundamentally different ways. Ignoring this is the root cause of most heating failures.

Metal Drums: The Robust and Conductive Choice

Steel drums are excellent conductors of heat. This allows for rapid, even heat distribution across the drum's surface. They have high structural integrity and can withstand significant temperatures (often exceeding 150°C/300°F), making them compatible with a wide range of silicone band heater types and higher power densities.

Plastic Drums: The Heat-Sensitive Container

Plastic drums are insulators, not conductors. Heat does not spread easily, creating "hot spots" directly under the heater. Crucially, most common plastic drums begin to lose structural integrity and can deform at temperatures as low as 50-60°C (122-140°F). This low heat distortion temperature is the single most important factor limiting your heating options.

⚠️ Critical Safety Notice: Applying a standard metal-drum heater to a plastic container is dangerous. The localized heat from a high-wattage band can soften, warp, or even melt the plastic wall, leading to drum failure and spillage of hazardous contents.

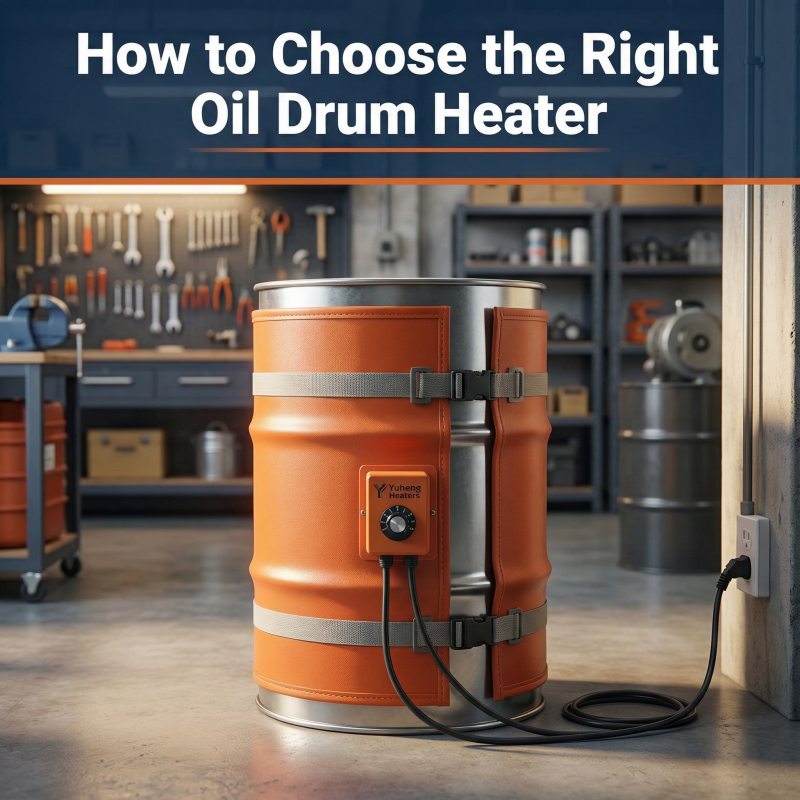

Selecting a Heater for a Metal Drum

For a standard 55-gallon steel drum, you have efficient and flexible options. The primary goal is even heat distribution and appropriate temperature control.

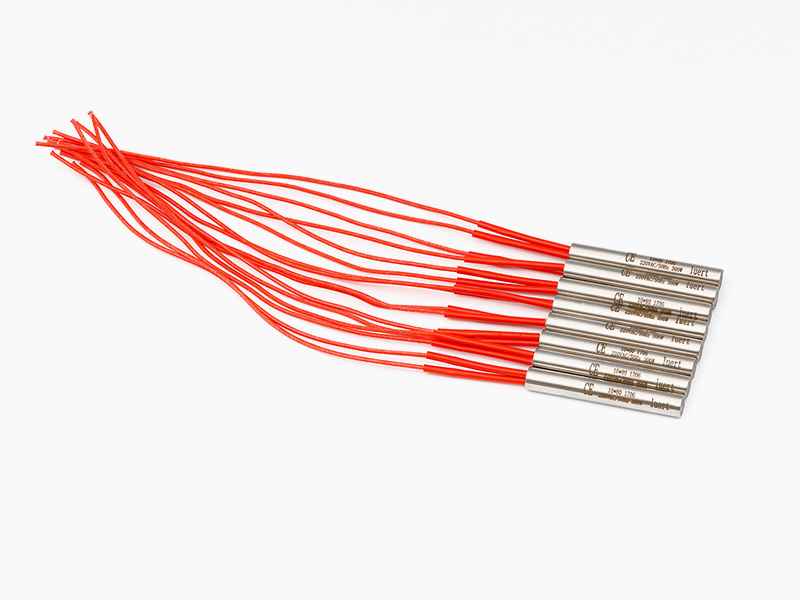

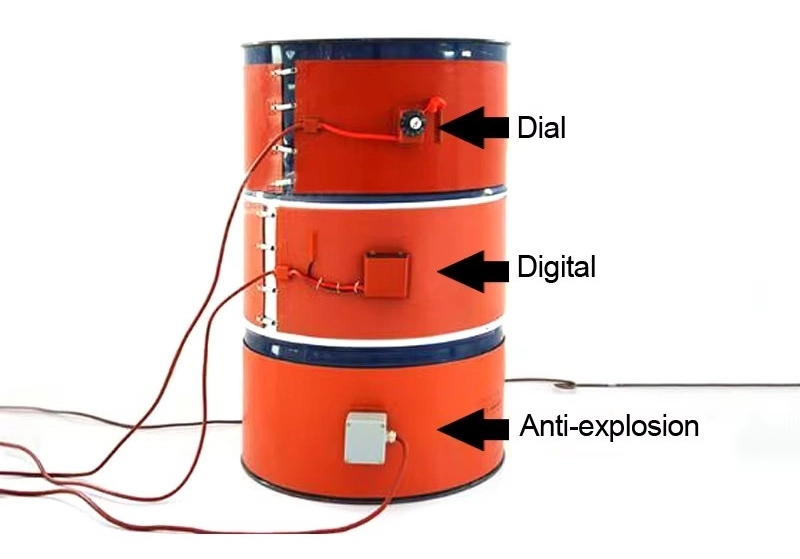

Silicone Rubber Band Heaters: The most popular choice. They are flexible, provide excellent surface contact, and come in various wattages and lengths. Look for models with integrated thermostats for precise control.

Drum Heating Jackets/Mantles: These wrap fully around the drum, providing superb thermal uniformity. Ideal for temperature-sensitive or high-viscosity contents.

Bottom Pad Heaters: Placed under the drum, these are excellent for freeze protection and maintaining temperature.

Pro Tip: For metal drums, ensure the heater is properly grounded and the drum is placed on a non-flammable surface. A silicone band heater with a NEMA 4 (watertight) rating is recommended for damp or washdown environments.

Selecting a Heater for a Plastic Drum

Heating a plastic drum requires a conservative, safety-first approach. The mantra is “low watt density and even distribution.”

Low-Watt-Density Silicone Heaters: Specialized bands designed for plastics operate at a much lower wattage per square inch (typically under 5-8 W/in²) to prevent hot spots.

Insulated Drum Jackets: These provide gentle, ambient warmth by trapping the drum's own heat, often avoiding direct contact with a high-temperature element.

Temperature Controllers are NON-NEGOTIABLE: An adjustable, reliable thermostat is mandatory to ensure the drum surface temperature never approaches its distortion point.

| Feature | Metal Drum Heater | Plastic Drum Heater |

|---|---|---|

| Max Recommended Surface Temp | High (e.g., 150°C+ / 300°F+) | Low (e.g., 50-60°C / 122-140°F) |

| Typical Watt Density | Medium to High (e.g., 15-25 W/in²) | Very Low (e.g., 3-8 W/in²) |

| Primary Safety Focus | Electrical safety, over-temperature for contents | Preventing drum deformation & failure |

| Heater Type Example | Standard Silicone Rubber Band | Low-Watt-Density Silicone Band or Insulating Jacket |

Power Calculation: A Simplified Approach

Avoid guesswork. Use this basic formula to estimate the wattage required to heat your drum's contents:

Power (Watts) ≈ [Volume (gal) x 8.34 x Specific Gravity x Temp Rise (°F)] / (Heating Time (hrs) x 3.412)

Example: Heating 55 gallons of oil (Sp.G. ~0.9) by 50°F in 2 hours requires roughly 1,500 watts. For a plastic drum, this total wattage must be spread over a larger area (low watt density) to be safe.

Why Silicone Band Heater Safety is Paramount

Silicone rubber heaters are preferred for their durability and heat transfer, but safety must be engineered in.

Built-in Thermostats & Limiters: Quality heaters include safety limiters that cut power if a fault occurs, a critical feature for plastic drums.

Proper Installation: The band must be snug and make full contact. A loose heater creates air gaps that lead to localized overheating.

Environment Rating: Ensure the heater is rated for your plant environment (chemical exposure, moisture, etc.).

Common Pitfalls to Avoid During Selection

Assuming “One Heater Fits All Drums”: This is the most expensive mistake you can make. Always verify drum material first.

Prioritizing Speed Over Safety: Trying to heat a plastic drum quickly by using a higher-wattage heater will result in failure.

Neglecting the Contents: Consider the flash point of your drum's contents. The heater's maximum temperature must stay well below this point.

Forgetting Ambient Conditions: Heating a drum in a freezing warehouse requires more wattage than in a mild workshop. Factor this into your calculation.

Final Recommendation: Start with the Drum, Not the Heater

The path to safe, efficient drum heating is clear: identify your drum material first. For robust metal drums, you have a range of effective 55 gallon drum heater options. For plastic drums, your strategy must be defined by caution, employing only low-watt-density solutions and rigorous temperature control.

By understanding these principles, you move from making a simple purchase to implementing a reliable thermal process. It’s this expertise that ensures operational continuity, protects your assets, and keeps your workforce safe. When in doubt, consult with a specialist who can help you match the precise heater technology to the unique requirements of your drum and its contents.

English

English Español

Español